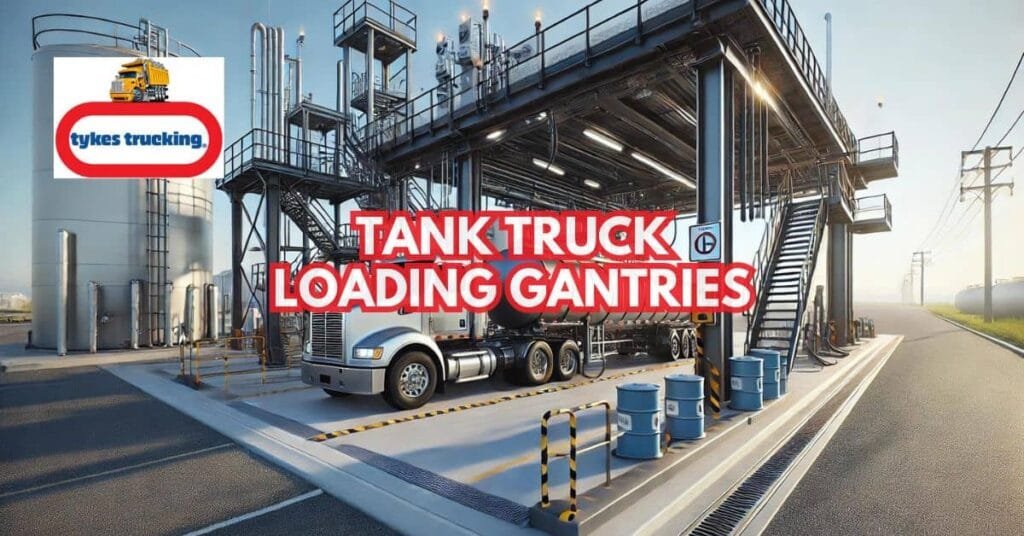

Tank truck loading gantries are specialized systems designed to make the transfer of liquids and gases into tank trucks safe, accurate, and efficient.

They are widely used in industries such as oil and gas, chemicals, and food and beverage, where controlled handling of materials is critical.

By automating loading operations, these systems help prevent spills, reduce human error, and protect both workers and the environment.

Understanding how tank truck loading gantries function, along with their key components and safety features, helps ensure reliable and consistent operations.

We’ll explain their main functions, types, benefits, and maintenance practices to help businesses choose and use these systems effectively.

1. The Challenge: Understanding Traditional Tank Truck Loading

Traditional tank truck loading often relies on manual processes, where operators must handle hoses, valves, and other equipment by hand.

This method can be physically demanding and increases the likelihood of errors, such as misalignment or incorrect valve operation.

Operators working on a platform may also be exposed to significant risks without proper fall protection, as they often need to access the top of the tank truck.

Additionally, manual handling of the loading arm can result in inconsistent loading rates and volumes, leading to operational inefficiencies.

Spills and contamination are common risks associated with these manual tasks, posing environmental and safety concerns.

Furthermore, the time required for manual loading slows down the overall process, reducing productivity.

Addressing these challenges is essential for companies looking to improve safety, efficiency, and consistency in tank truck loading operations.

🚚 How to Choose the Right Dump Truck Hauling Services in Marikina for Your Needs

2. The Solution: Introducing Tank Truck Loading Gantries

Tank truck loading gantries provide a modern, engineered solution to the challenges of traditional loading methods.

These systems automate key aspects of the process, significantly reducing the need for manual handling of hoses and valves.

Engineers design these gantries with advanced safety features, including safety cages that protect operators working near or on top of the tanker.

These safety cages provide a physical barrier to prevent falls, ensuring a safer work environment.

Gantries also integrate automatic shutoff valves, grounding systems, and precision controls that ensure consistent loading rates and volumes, improving both safety and efficiency.

By eliminating much of the manual intervention, the risk of human error is minimized, which reduces spills and accidents.

Overall, tank truck loading gantries are a comprehensive solution that improves safety, consistency, and operational efficiency in loading operations.

🚚 Understanding Tank Truck Hoses: Types, Uses, and Maintenance

3. Embracing Technological Innovations in Gantry Systems

Modern tank truck loading gantries are evolving with cutting-edge technologies to boost safety and operational efficiency.

Many gantries now feature steel structures that provide durability and support for advanced equipment, while also incorporating canopies to shield both operators and equipment from harsh weather conditions.

IoT devices integrated into these systems enable real-time monitoring, allowing for predictive maintenance and timely repairs to minimize downtime.

Smart automation, powered by AI and machine learning, further optimizes the loading process by adjusting parameters in real-time, ensuring consistent and safe operations.

Operators can also benefit from remote monitoring capabilities, allowing them to control gantry systems without having to be physically present on-site.

Also, gantries now often include ergonomic stair designs to improve safe access for maintenance and inspection tasks.

These innovations not only enhance day-to-day operations but also future-proof gantry systems for evolving industry demands.

🚚 How to Choose a 26-Foot Flatbed Trailer for Your Business

4. Integrating Gantries with Terminal Automation and Business Systems

Modern tank truck loading gantries can connect directly to terminal automation systems to make loading smoother and safer.

These systems identify each truck through RFID tags or access cards and automatically approve the correct loading setup.

The gantry then sends real-time data to inventory and billing systems so that product amounts and delivery records stay accurate.

This digital link removes the need for manual paperwork and reduces mistakes caused by human input.

By working together as one connected system, gantries help terminals run faster, safer, and with better control over their daily operations.

🚚 Reefer Container Troubleshooting: A Cool Guide to Keeping Your Cargo Fresh

5. Unlocking Efficiency and Safety: Benefits of Tank Truck Loading Gantries

The use of tank truck loading gantries brings many benefits that greatly improve how facilities load and unload materials.

Automated systems help move liquids or gases into a tanker truck faster and with fewer mistakes.

They also reduce the time operators spend handling hoses and valves, which lowers the risk of spills and injuries.

These systems can control flow rates and shut off automatically when a tank is full, keeping both workers and products safe.

The ability to load and unload more trucks in less time increases productivity and reduces waiting times.

Consistent and accurate operation also helps keep records precise and supports compliance with safety and environmental rules.

All in all, tank truck loading gantries make each loading process safer, faster, and more reliable for operators and facilities.

🚚 When to Use Flatbed Hauling Services: Key Considerations for Shippers

6. Choosing Your Weapon: Exploring Different Types of Tank Truck Loading Gantries

There are several types of tank truck loading gantries, each built to handle different products and safety needs.

A top-loading arm system is often used when liquids can safely flow into the tank from above, making it a simple and affordable choice for many operations.

This setup works well for materials that do not release dangerous vapors during loading.

In contrast, bottom-loading systems connect to fittings at the bottom of the tanker, keeping the process enclosed to reduce vapor emissions and improve worker safety.

Bottom loading also helps achieve faster and more uniform filling because multiple compartments can be filled at once.

Some gantries are built with heating or cooling features to handle products that must stay at certain temperatures.

Understanding how each loading type functions allows facilities to choose the system that best matches their product properties and safety requirements.

🚚 How Expedited Trucking Services Save the Day and Your Deadlines

7. Safety First: Essential Safety Features of Tank Truck Loading Gantries

Modern tank truck loading gantries include several safety features that protect both workers and equipment during operation.

A well-designed loading and unloading platform provides a stable surface for operators to work on while connecting hoses and monitoring product flow.

The platform is often equipped with guardrails and non-slip surfaces to prevent falls or slips, especially in wet or oily conditions.

Folding stairs are another important feature, giving operators safe and adjustable access to the top of the tanker when needed.

These stairs can be raised or lowered easily, keeping movement controlled and reducing the risk of accidents.

Along with these structural features, automatic shutoff valves and emergency stop buttons ensure quick response in case of overfill or malfunction.

Together, these safety components create a secure working environment that minimizes risks during all loading and unloading activities.

🚚 How to Choose the Right Trucking and Hauling Company

8. Finding the Perfect Fit: Selecting the Right Tank Truck Loading Gantry for Your Needs

Choosing the right tank truck loading gantry requires a thorough assessment of your operational requirements.

Consider the type of products being loaded, as different substances may necessitate specific features or materials in the gantry.

The operational environment, such as whether the loading will occur indoors or outdoors, can also influence the choice of gantry.

It’s important to evaluate the loading capacity and speed needed to meet your production demands.

Customization options, such as adjustable arms or specific safety features, can further tailor the gantry to your unique needs.

🚚 Why Hydraulic Cylinder for Dump Trucks Is Essential for Heavy-Duty Operations

9. Safety Never Sleeps: Essential Considerations During Tank Truck Loading Operations

Continuous vigilance is key to maintaining safety during tank truck loading operations.

Operators should be thoroughly trained on all equipment and safety protocols to handle any emergencies effectively.

Regular safety checks and audits are crucial in identifying potential hazards and ensuring compliance with safety standards.

It’s also important to have clear communication and signaling systems in place to coordinate the loading process smoothly.

Proper use of personal protective equipment (PPE) and adherence to safety procedures can significantly reduce the risk of accidents.

🚚 How Many Tons of Gravel in A Dump Truck

10. Maintaining Peak Performance: Inspection and Maintenance of Tank Truck Loading Gantries

Regular inspection and maintenance are essential to keep tank truck loading gantries operating at peak performance.

Routine checks should include inspecting hoses, valves, and connections for wear and tear or leaks.

Lubricating moving parts and replacing worn components can prevent breakdowns and extend the life of the gantry.

Scheduling periodic maintenance ensures that all safety features, such as emergency stop systems and grounding mechanisms, are functioning correctly.

Keeping detailed maintenance records can help track the gantry’s condition and plan for future repairs or upgrades.

🚚 How to Choose the Right Service for Aggregate Delivery in Marikina

11. Staying Compliant: Regulations and Compliance for Tank Truck Loading Gantries

Compliance with regulations is crucial for the safe and legal operation of tank truck loading gantries.

These regulations may vary by region but generally include standards for safety, environmental protection, and operational procedures.

Regular audits and inspections by regulatory bodies ensure that gantries meet all required standards.

Staying updated with changes in regulations helps avoid non-compliance issues, which can result in fines or operational shutdowns.

Ensuring compliance not only enhances safety but also protects the company’s reputation and legal standing.

🚚 Efficient Hauling with Professional Dump Trucks

12. Investing in Your Future: Cost Considerations and ROI of Tank Truck Loading Gantries

Investing in tank truck loading gantries requires careful consideration of costs and potential returns.

While the initial investment may be significant, the long-term benefits often justify the expense.

Automated gantries can reduce labor costs and increase operational efficiency, leading to substantial savings over time.

Improved safety features can lower the risk of accidents and associated costs, such as medical expenses and legal fees.

Evaluating the total cost of ownership, including maintenance and potential productivity gains, helps in understanding the true ROI of these systems.

🚚 Bulk Hauling Dump Truck Services in Marikina City

💡 Conclusion

Tank truck loading gantries represent the future of efficient and safe loading operations.

As technology advances, these systems will continue to evolve, offering even greater automation and enhanced safety features.

Adopting modern gantries can significantly improve productivity, reduce operational risks, and ensure compliance with safety regulations.

Staying informed about the latest developments in gantry technology will help businesses maintain a competitive edge.

By investing in advanced loading systems, companies can ensure long-term operational success and safety.

❓ FAQs

1. What is the main purpose of a tank truck loading gantry?

A tank truck loading gantry is designed to safely transfer liquids or gases into tank trucks.

It helps control the loading process to prevent spills and overflows.

The gantry also protects workers by reducing the need for manual handling of equipment.

2. What industries use tank truck loading gantries?

These gantries are commonly used in the oil and gas, chemical, and food and beverage industries.

Any facility that loads or transfers large volumes of liquids or gases can benefit from them.

They ensure precise, safe, and efficient product handling during loading operations.

3. What are the differences between top-loading and bottom-loading gantries?

Top-loading gantries load products from above and are simpler to install.

Bottom-loading gantries load from below and are safer for flammable or hazardous products since they reduce vapor release.

The choice depends on the type of material, safety needs, and operating environment.

4. How often should a tank truck loading gantry be inspected or maintained?

Regular inspections should be done based on usage and manufacturer guidelines.

Critical parts such as hoses, valves, and safety systems should be checked for wear and leaks.

Routine maintenance keeps the system reliable and prevents costly breakdowns.

5. Why is automation important in tank truck loading gantries?

Automation ensures consistent loading speeds and accurate quantities, reducing human error.

It also improves safety by limiting direct contact between workers and hazardous materials.

Modern automated gantries can connect to terminal systems for better data control and efficiency.

😉 Our Services

Tykes Trucking Services is your go-to provider for reliable aggregate delivery and hauling services.

Our dedicated team ensures the timely and efficient transport of materials for your construction and landscaping needs.

With a commitment to quality and customer satisfaction, we make sure every job is done right.

Reach us by phone at 0917-543-5019, via our website’s contact page, or by going to our Facebook page.

Choose Tykes Trucking Services for seamless and dependable hauling solutions.