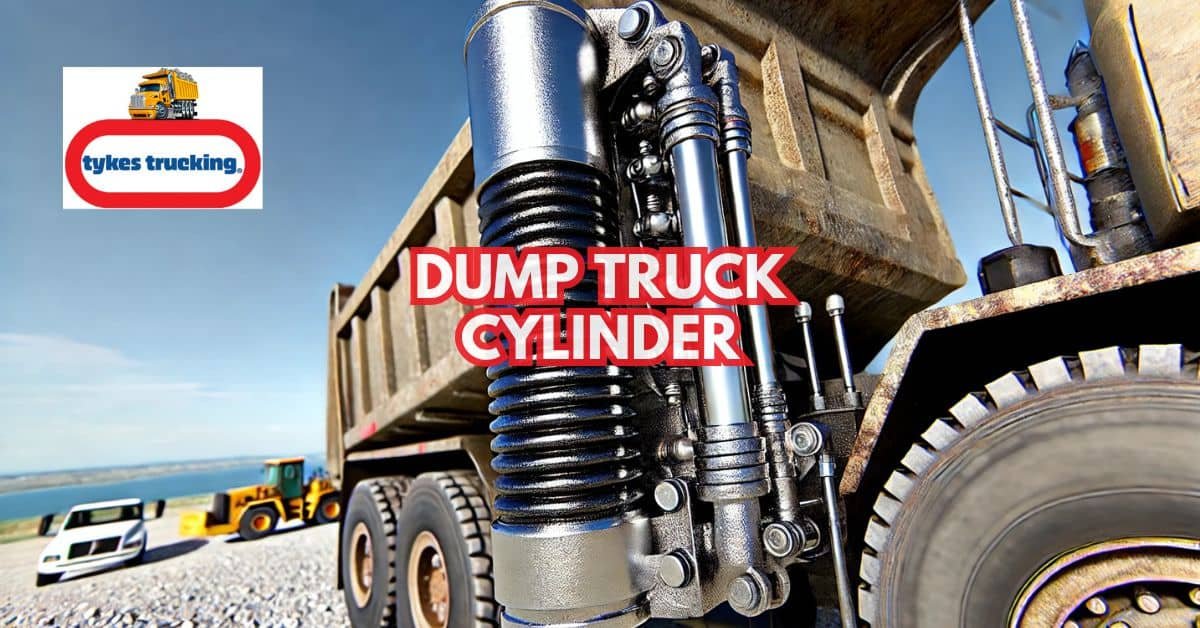

A dump truck cylinder is a hydraulic component that helps lift the bed of the truck to dump heavy loads.

It works by using pressurized hydraulic fluid to extend or retract the cylinder, which in turn tilts the truck bed.

The cylinder’s main job is to bear the load and ensure smooth lifting and lowering of the truck bed.

It is a critical component for heavy-duty tasks, which means proper maintenance is essential.

Understanding how it functions can help identify issues when the cylinder starts malfunctioning.

1. Common Signs That Your Dump Truck Cylinder is Malfunctioning

Signs of a malfunctioning dump truck cylinder include slow or erratic movement of the bed, unusual noises, or a failure to lift.

You might also notice leaking hydraulic fluid, which could point to a seal or internal damage.

Another sign is the bed lowering too quickly, which can be dangerous and indicates a problem with hydraulic control.

If you experience jerking movements during operation, it could signal air in the hydraulic system.

Catching these signs early can save time and money on repairs.

🚚 The Ultimate Guide to Truck Driver Gloves: Grip It and Rip It

2. How to Check for Hydraulic Fluid Leaks in Your Dump Truck Cylinder

Look for visible leaks around the cylinder and along the hydraulic lines.

Pay close attention to the connections and fittings, as these are common areas for leaks to develop.

If you spot a puddle under your truck or see fluid seeping from the cylinder, a leak is likely present.

Low fluid levels due to a leak can lead to poor performance or even damage to the hydraulic system.

Addressing leaks promptly will prevent further issues with the cylinder.

🚚 Understanding Dump Truck Capacity in Tons: What You Need to Know

3. Inspecting the Cylinder Rod for Damage or Wear

Carefully inspect the cylinder rod for any signs of rust, dents, or scratches.

Damage to the rod can lead to seal wear, which can then cause fluid leaks.

A bent or damaged rod can also cause misalignment, making the cylinder ineffective.

If rust is present, it should be cleaned off, and any significant corrosion may require rod replacement.

If you notice any significant wear, the rod may need to be repaired or replaced to avoid further damage.

🚚 Bucket Truck Accessories: Power Up Your Efficiency and Safety

4. How to Assess the Quality and Level of Hydraulic Fluid

Check the hydraulic fluid level to ensure it’s within the recommended range.

Low fluid can cause the cylinder to fail or work poorly, leading to operational issues.

Assess the quality of the fluid by examining its color and clarity—if it appears dark or contaminated, it’s time to replace it.

Contaminated fluid can lead to wear on other hydraulic components and reduce efficiency.

Regularly maintaining the fluid level and quality helps keep the cylinder in top shape.

🚚 Dirt Dump Truck Safety: Essential Tips for Operators and Construction Workers

5. Testing the Hydraulic Pump and System Pressure for Issues

If your dump truck cylinder is struggling to lift, the hydraulic pump might be at fault.

Test the pump to ensure it’s providing enough pressure to lift the bed effectively.

Low system pressure can result from a faulty pump or blockage in the hydraulic lines.

Use a pressure gauge to measure the system’s pressure, comparing it to the manufacturer’s recommendations.

Inadequate system pressure often leads to sluggish or unresponsive cylinder movement.

🚚 Exploring Advanced Features for Your Flatbed Truck Body

6. How to Examine and Replace Damaged Cylinder Seals

Cylinder seals prevent hydraulic fluid from leaking and keep the system running smoothly.

Examine seals for signs of cracking, tearing, or wear, as these issues can lead to leaks.

Damaged seals will also allow air to enter the hydraulic system, causing jerky movement.

Carefully replace any damaged seals to restore the hydraulic system’s integrity.

Replacing the seals promptly can prevent larger issues such as loss of power or hydraulic fluid contamination.

🚚 What Are Dump Truck Brokers and How Do They Operate in the Transportation Industry?

7. Troubleshooting Control Valves and Hydraulic Lines for Blockages

Check the control valves and hydraulic lines for blockages, which can reduce pressure and affect cylinder performance.

Debris or buildup inside the lines can restrict fluid flow, causing erratic movement or failure to lift.

Inspect valves to ensure they open and close smoothly without resistance.

Cleaning or replacing blocked lines can restore full functionality and improve the efficiency of the system.

Regular inspection of valves and lines helps avoid unexpected downtime.

🚚 Best Truck Driver Boots for All Conditions: Don’t Get Stuck in the Mud

8. How to Identify and Remove Air from the Hydraulic System

Air trapped in the hydraulic system can cause the cylinder to move unevenly or jerk when operating.

Bleeding the system helps release trapped air, which should be done when fluid levels have been low or after a repair.

Follow the correct procedure to bleed each part of the hydraulic system to ensure smooth operation.

Failure to remove air can lead to damage and decreased efficiency.

Properly bleeding the system will help maintain smooth operation of the dump truck cylinder.

🚚 How a Dump Truck Course Can Help You Meet Industry Safety Standards

9. Checking Cylinder Mounting Points for Stability

Inspect the cylinder’s mounting points to ensure they are secure and free from damage.

Loose or damaged mounts can lead to misalignment, which affects the cylinder’s performance and stability.

Tighten any loose bolts and check for cracks or wear on the mounting brackets.

Misaligned mounts can place unnecessary stress on the cylinder, leading to early failure.

Tightening or repairing these mounting points can help restore stability and prolong the life of the cylinder.

🚚 How to Find the Best Aggregates Delivery in Cainta for Your Construction Needs

10. When to Call a Professional for Dump Truck Cylinder Repairs

If troubleshooting doesn’t solve the problem, it may be time to call a professional.

Complex issues, like major internal cylinder damage or persistent leaks, need specialized tools and expertise.

Professionals can accurately diagnose problems that are beyond basic maintenance.

Attempting to repair major issues without the right skills can lead to further damage.

Calling an expert can save time and prevent further harm to the hydraulic system.

🚚 Tykes Trucking Services Marikina

💡 Conclusion

Routine inspections and maintenance can help avoid common dump truck cylinder problems.

Regularly checking for leaks, worn parts, and proper fluid levels will ensure your dump truck is ready for heavy-duty work.

Always act quickly when issues arise to keep your equipment in good working order.

Replacing damaged parts before they fail completely can save both time and money.

Proper care will keep your dump truck cylinder functioning effectively for years to come.

😉 Our Services

Looking for reliable hauling services and aggregate delivery?

Tykes Trucking Services is here to get the job done efficiently and on time.

Whether you need sand, gravel, or other materials delivered, we’ve got you covered with our top-notch fleet and experienced team.

Reach out to us today at 09175435019, send us a message on our Facebook page, or connect via our website’s contact form.

Choose Tykes Trucking Services—delivering excellence every mile!